Sand Blasting Services

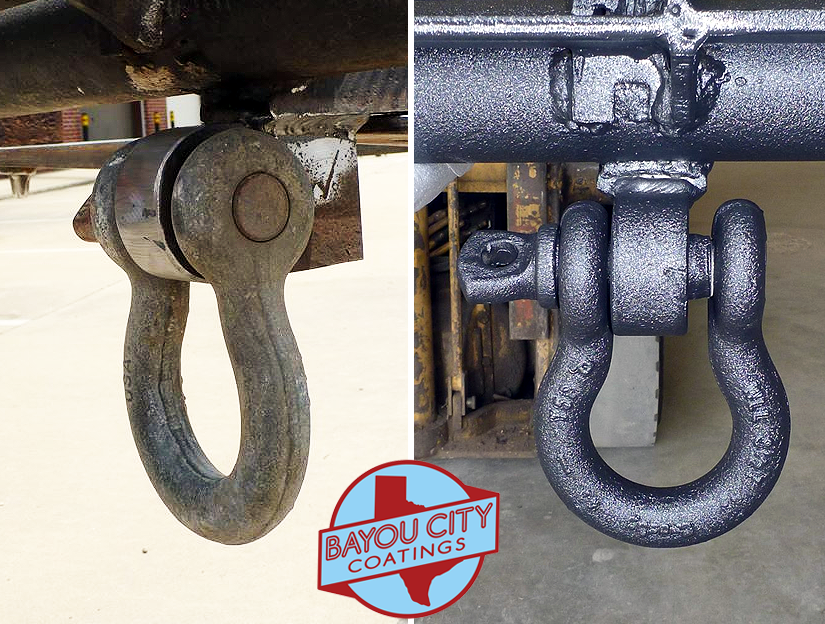

Sand blasting is the process of using high pressure to blast sand (or other media) onto a surface to remove a coating or rust. Sand blasting is powerful, quick, thorough, and safe. It is generally the best way to prepare an object for high performance coatings like powder coating.

Sand blasting, also referred to as “abrasive blasting,” is a mature technique with many variations for different applications. It’s been indevelopment for over 140 years. The first abrasive blasting process was patented by Benjamin Chew Tilghman on October 18, 1870. Examples of the work that can be done are the engraving on tombstones, fine engraving on metal, ceramic or glass objects, and the bas-relief or 3D shaping of material.

Sometimes sand blasting is not enough. When necessary, a degreasing process is also needed to insure the best possible adhesion of the powder coat.

USES OF SANDBLASTING

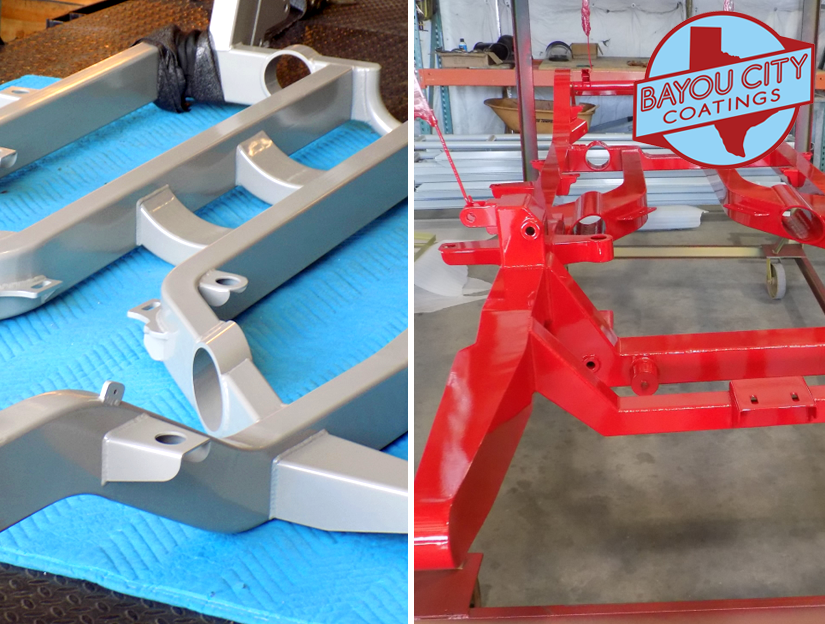

Besides its basic cleaning role, sandblasting is also used to prepare the surface of an object for different final finishes. A rough object can be made smooth and a smooth object can be made rough. Parts of objects can also be masked for even more options in the final appearance.

It’s easy to see that sand blasting allows Bayou City Coatings control of your project in many ways:

- Removal of rust, sand, scale and paint from fabricated parts for the best adhesion

- Surface preparation for different final finishes—smooth, glossy, or matte prior to powder coating

- Roughening of engine components

- Providing a matte or shiny surface

- Restoring very old objects to “new” condition

- Creating pride-of-ownership details to your off-road buggy or daily driver